Your cart is currently empty!

The Leaders in Hi Flow Water Pumps

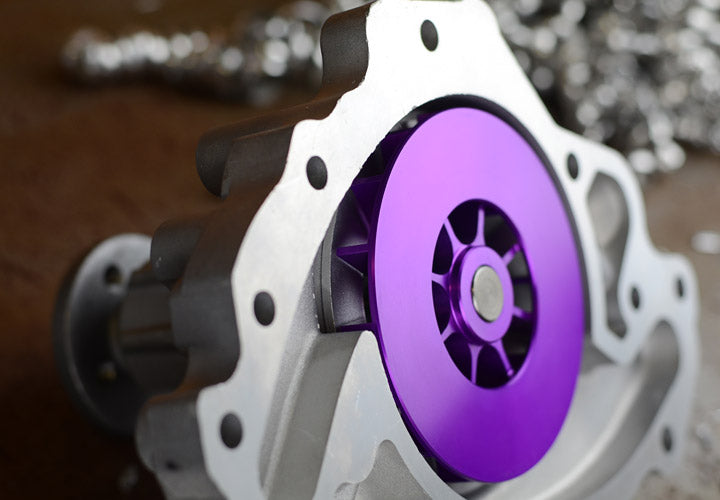

FlowKooler water pumps prevent engine overheating. Each impeller is designed to generate higher flow rates and increase system pressure. Increasing coolant flow rate through the block reduces the cycle time between the engine and the radiator providing more opportunity for heat exchange. When flow rate is maximized, the higher flow rates raise engine block pressure to prevent the formation of steam pockets in the water jacket and the vapor barrier that can cause hot spots on cylinder walls.

We Take the Heat Out With Design.

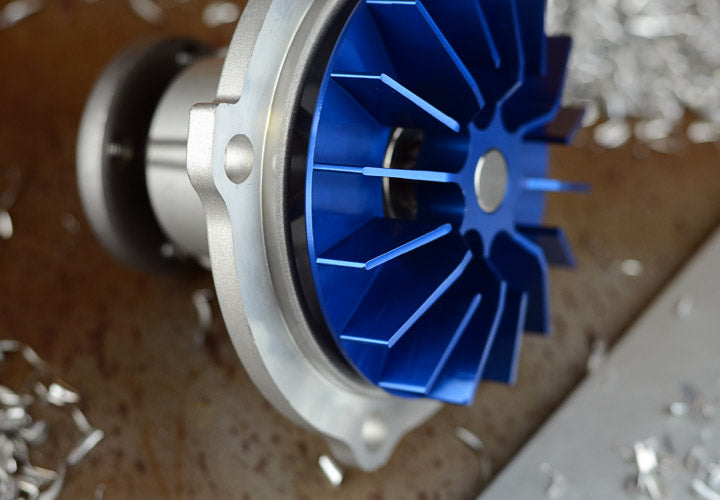

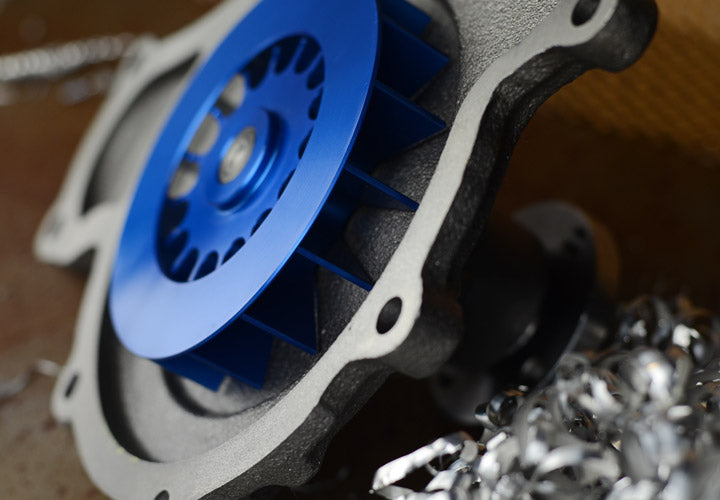

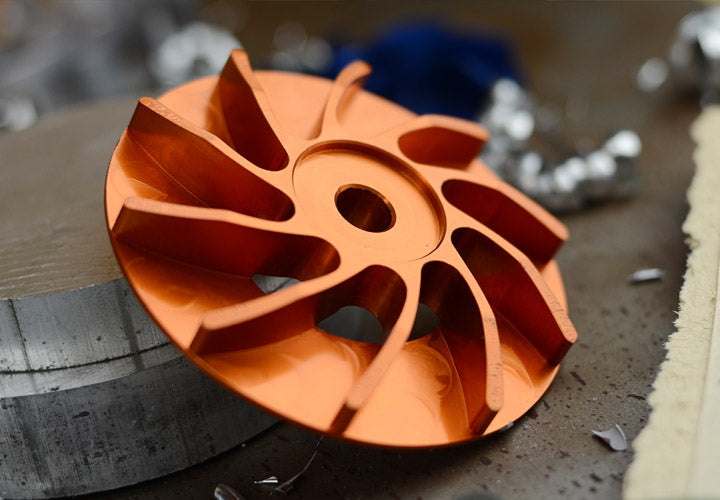

Each of our billet aluminum impellers is precision machined to achieve tighter clearances between the vanes and the casting volute. Each is shrouded to contain the flow. This design combination generates higher flow rates that reduce the cycle time between the source and sink. It is that simple.

More Efficient Flow Curve. More Horsepower.

Our impeller designs achieve a more efficient flow curve to conserve valuable horsepower. Less power used to move the coolant through your system means more power you have to move your tires down the road.

Higher Flow Rates. Higher Block Pressure.

Higher flow rates help cool at lower speeds but they also raise the block pressure at higher rpm. Building that pressure helps prevent hot spots & steam pockets from forming on cylinder walls. Higher pressure also prevents early detonation and reduces the onset of cavitation.

All good stuff!

Corrosion Destroys. FlowKooler Protects.

Your coolant begins to deteriorate almost immediately. FlowKooler CNC machines each impeller from corrosion resistant 6061 billet aluminum and anodize finishes each one with a Military Spec MIL-A-8625 Type II Class II surface coating.

Cooling Resources

-

SBC Coolant flow and heater hose connection guide

Coolant flow path through the block, radiator and heater hoses

Read More -

How much do your pumps flow? About as long as a piece of string.

How long is a piece of string? This is an idiomatic rejoinder to a question that is difficult to answer.

Read More -

Pulley ratios and hi flow water pumps

So should I over drive my pulley or underdrive my pulley with a hi flow FlowKooler waterpump?

Read More -

Deciphering small block Ford timing chain covers

If you are trying to find out what timing chain cover you have in your small block ford this may help

Read More