Your cart is currently empty!

1647 early 1969 Pontiac 4" tall "11 Bolt" water pump

$192.78

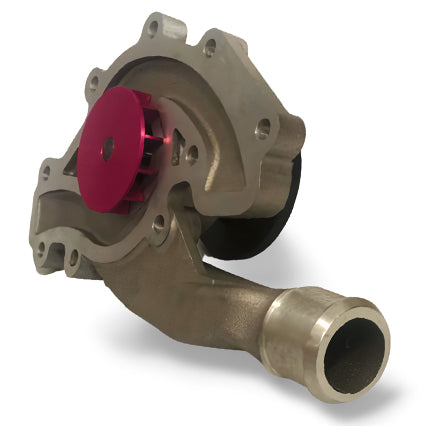

1647 early 1969 Pontiac 4" tall "11 Bolt" water pump

$192.78

This is the elusive 1969 only "short" pump e.g. 4" tall. Classic Pontiacs run hot so Flowkooler designed a high flow 11 bolt pump with a CNC machined billet impeller. With increased vane count and a reduced plate-to-impeller vane clearance it achieves higher flow rates, higher head pressure and a more efficient flow. The impeller color is due to Type II Class II military grade surface coating which protects against corrosive fluids.

FlowKooler introduced the first hi flow pumps and continues to improve impeller design. Why is increased flow so important to cooling a hot Pontiac engine? Because it has been proven time and time again that reducing the cycle time between the heat source and the heat sink creates more opportunities to shed heat and drop engine temperatures.

From 0-3,300 RPM…Nothing Beats a FlowKooler!

Reducing the gap between the backing plate and the impeller

Way back when the internet was young a George Kujanski made a statement on a forum about his experience in reducing clearance between impeller vane and backing plate. Ever since our phones ring with questions about the clearance. George was correct; when you reduce the clearance in a centrifugal pump you will increase the pressure differential and, concomitantly. increase the flow. We machine taller impeller vanes into our pumps for this very purpose. However as a manufacturer, we cannot machine each pump for the myriad of aftermarket plates and/or distorted, warped or corroded OE plates, Furthermore, we cannot ensure that the person modifying has any experience in forming metal. For this reason we will not make a recommendation beyond; "as close as you can get without touching."

George pressed his plate to a .100" clearance and reported anecdotally, "a drastic change in my engine temps with no other changes". As a frame of reference, this is roughly the thickness of three sheets of paper. If you elect to close the impeller-to-plate gap you have George's blessing.

N.B. Clearances that results in an impeller vane to backing plate interference will cause friction and failure and so we (unlike George) cannot recommend a specific clearance. Owner modifications to the Pontiac part design are performed at the owner's discretion and FAILURE TO MAINTAIN ADEQUATE CLEARANCE WILL VOID ALL WARRANTY.

*Note: This pump is for the 1969 400 blocks with casting #9796351. The 1969 400 pump measures 4". The 4-1/2" taller more common pump is 1649.

| General Specifications: | ||

|---|---|---|

| Type of Material of Pump Body | Cast Iron | |

| Number of Blades on Impeller | 16 CNC Aluminum | |

| Direction of Rotation | CW | |

| Fan Hub Working Height | 4" | |

| Other Special Features: | ||

|

||

| Parts Contained in Box: | ||

| Mounting Gasket, Installation Sheet, FlowKooler Decal | ||

| Make | Model | Year | Block | CID | Liters |

|---|---|---|---|---|---|

| PONTIAC | FIREBIRD | 1969 | V8 | 350 | 5.7L |

| PONTIAC | LEMANS | 1969 | V8 | 350 | 5.7L |

| PONTIAC | SAFARI | 1969 | V8 | 350 | 5.7L |